Technology

Wet fusion technology

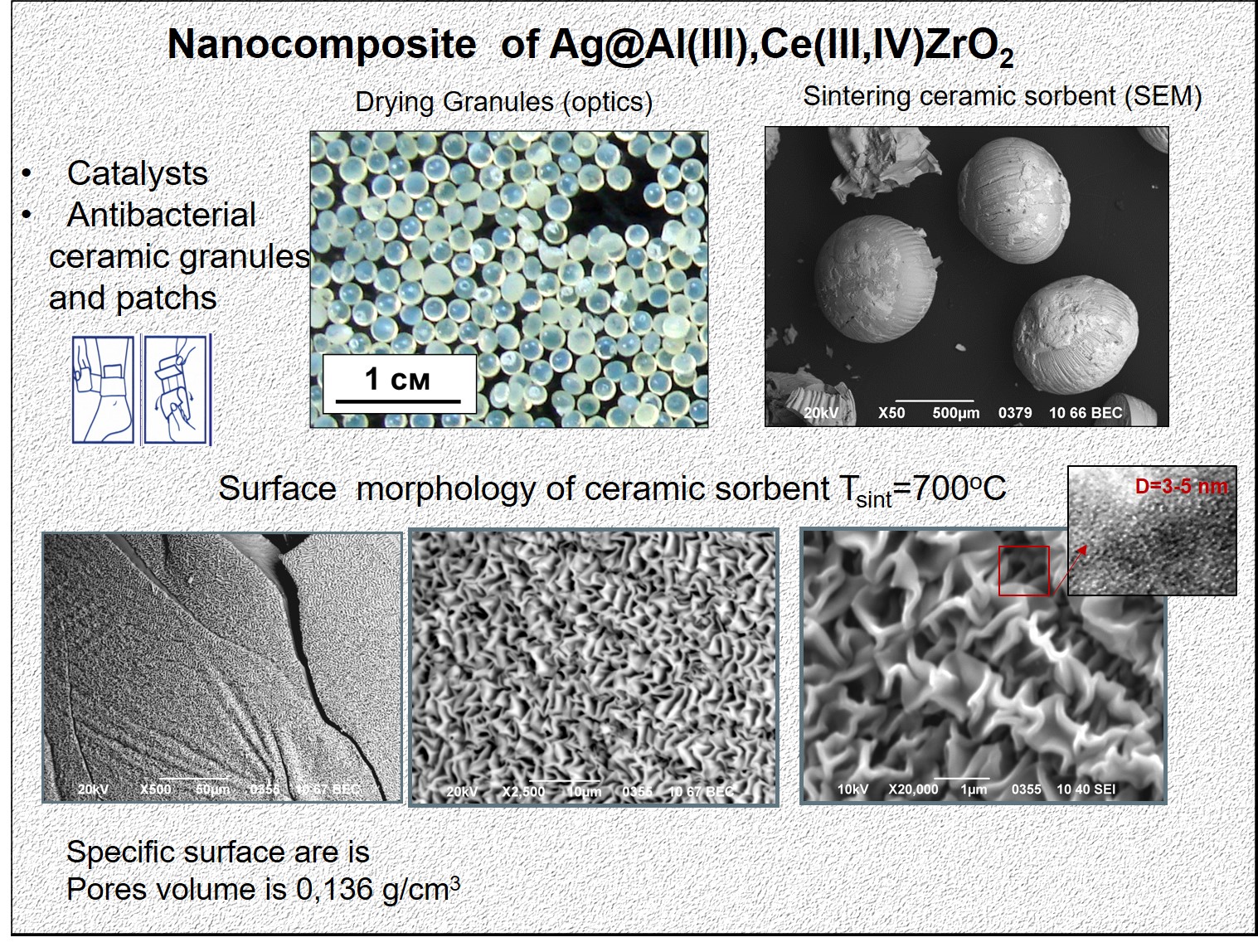

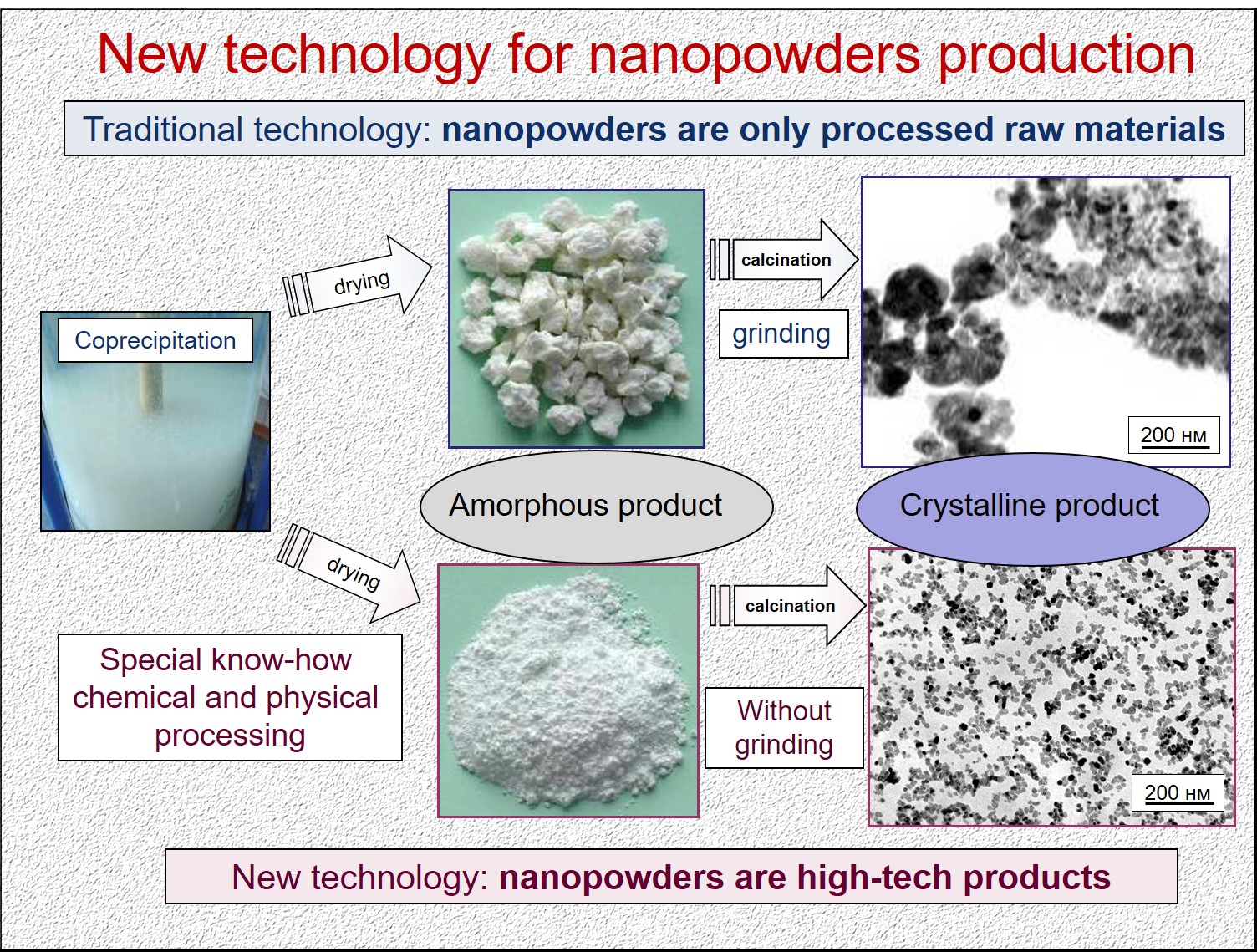

The uniqueness of the technology lies in the use of physical and chemical methods of modification in the process of synthesis of oxide systems by chemical deposition. Technological methods of physical and chemical modification, built into the technological process, allow achieving optimal conditions for obtaining a product with the required properties, reducing the drying time of the product, and eliminating the grinding stage used in traditional industrial production.

A feature of the technology for producing oxide nanopowders is the staging of the synthesis of a hydrogel-amorphous xerogel – oxide, which makes it possible to stop the synthesis process at each separate stage and include the necessary modification techniques at a certain stage. This allows, along with the optimal selection of the type of feedstock (the type of salt and the precipitating agent), the concentration of the initial reagents, the range of used deposition pH values, the nature and amount of the introduced dopant, as well as the drying and annealing modes of the resulting product, to control the structure and properties of the material in within one technological approach,

The technology is capable of producing simple, complex and composite oxide materials with characteristics for a specific task.

CVD Technology

The uniqueness of the technology lies in the use of physical and chemical features of the oxidation of metal powders. Allows you to create oxide powders of complex shapes (used for ZnO, NiO).

The capabilities of the technology are an additional chemical modification with the techniques of small chemistry, which makes it possible to obtain complex functional systems with characteristics for a specific task.

Areas of work

-

Synthesis of simple, multicomponent and composite nanomaterials for scientific research;

Synthesis of simple, multicomponent and composite nanomaterials for scientific research; -

Transfer of developed materials to production

Transfer of developed materials to production

-

Scientific and technological service for the characterization of nanomaterials

Scientific and technological service for the characterization of nanomaterials

-

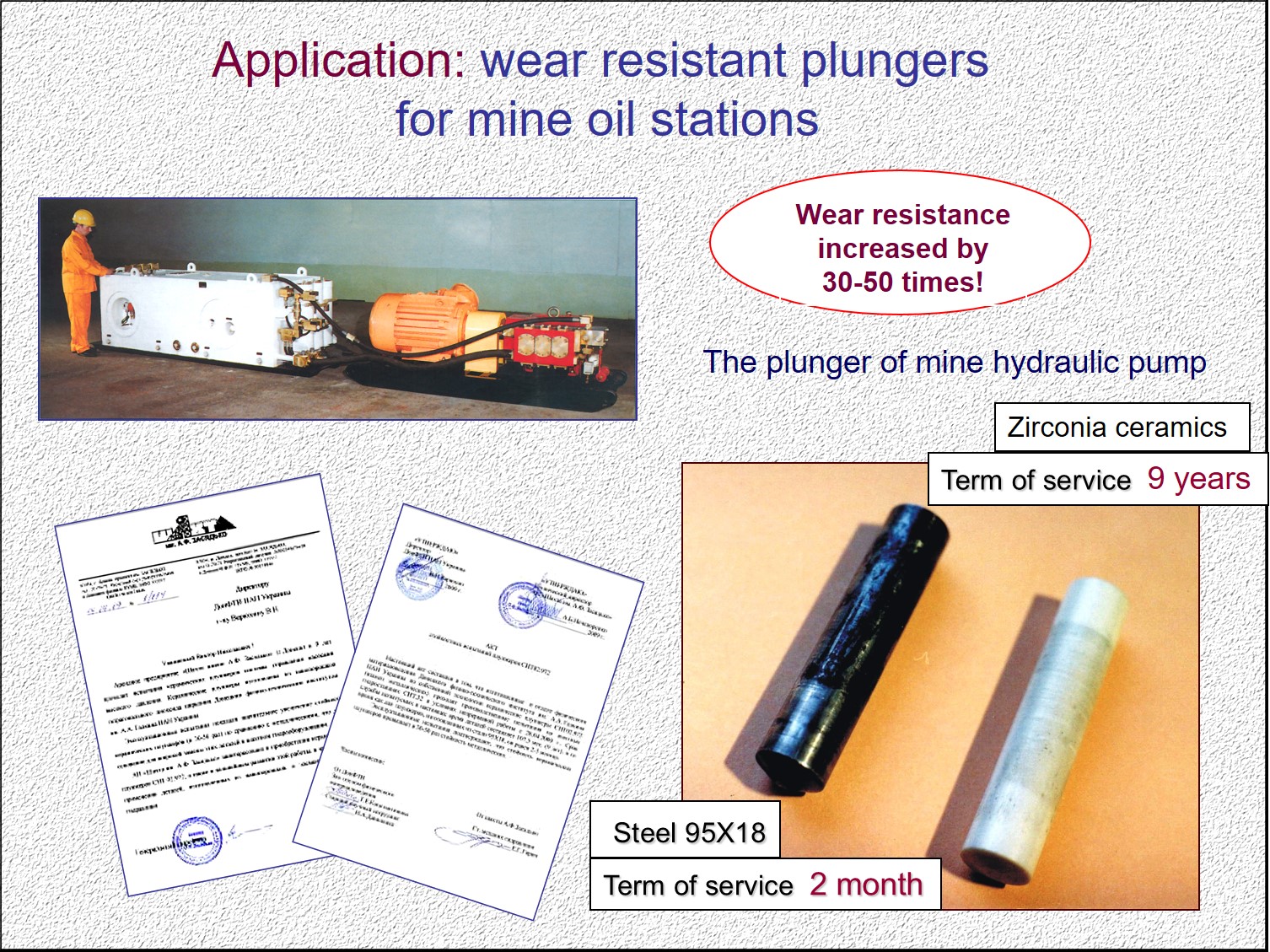

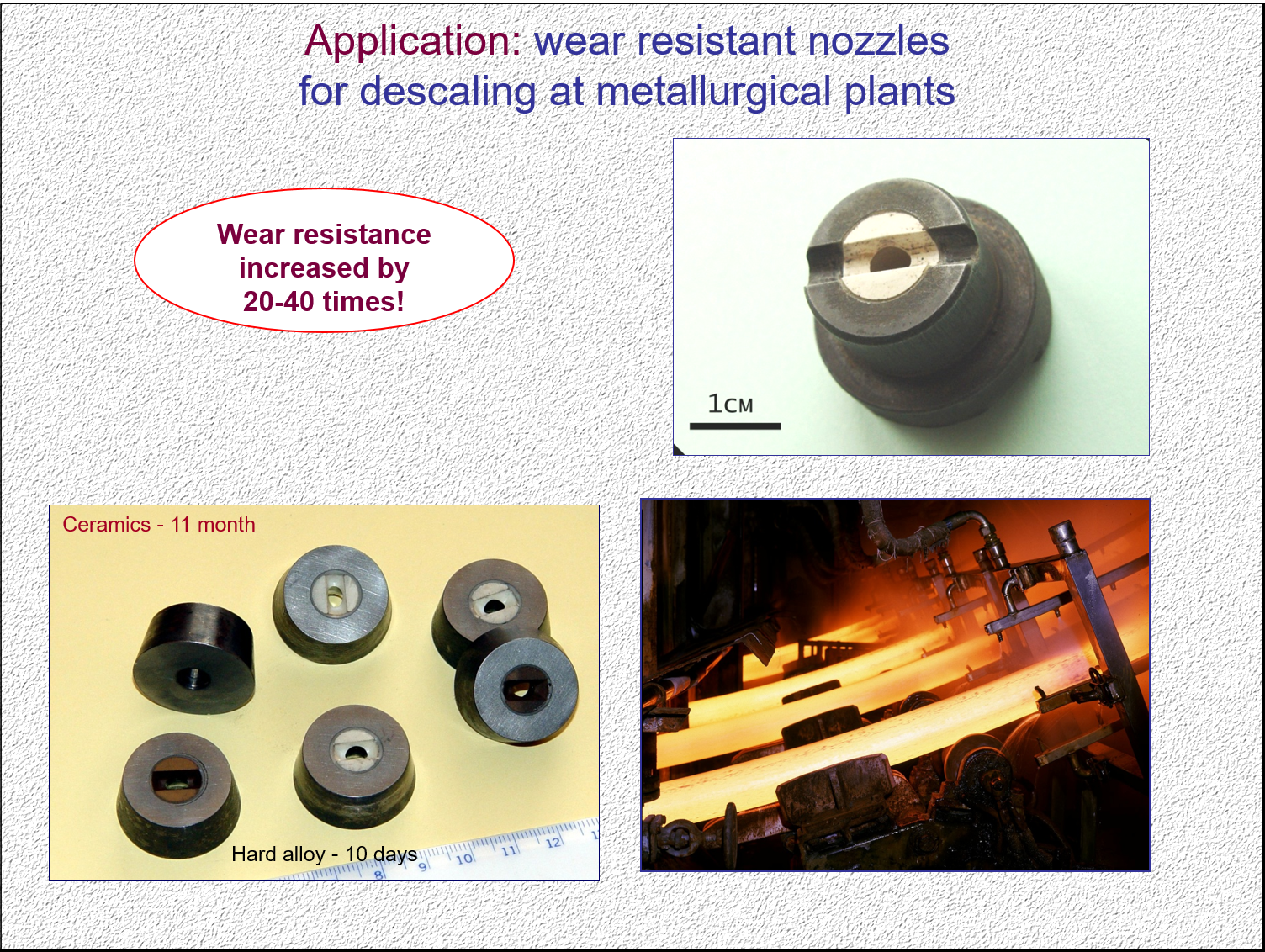

Solving the problems of improving the properties of oxide ceramic materials

Solving the problems of improving the properties of oxide ceramic materials

-

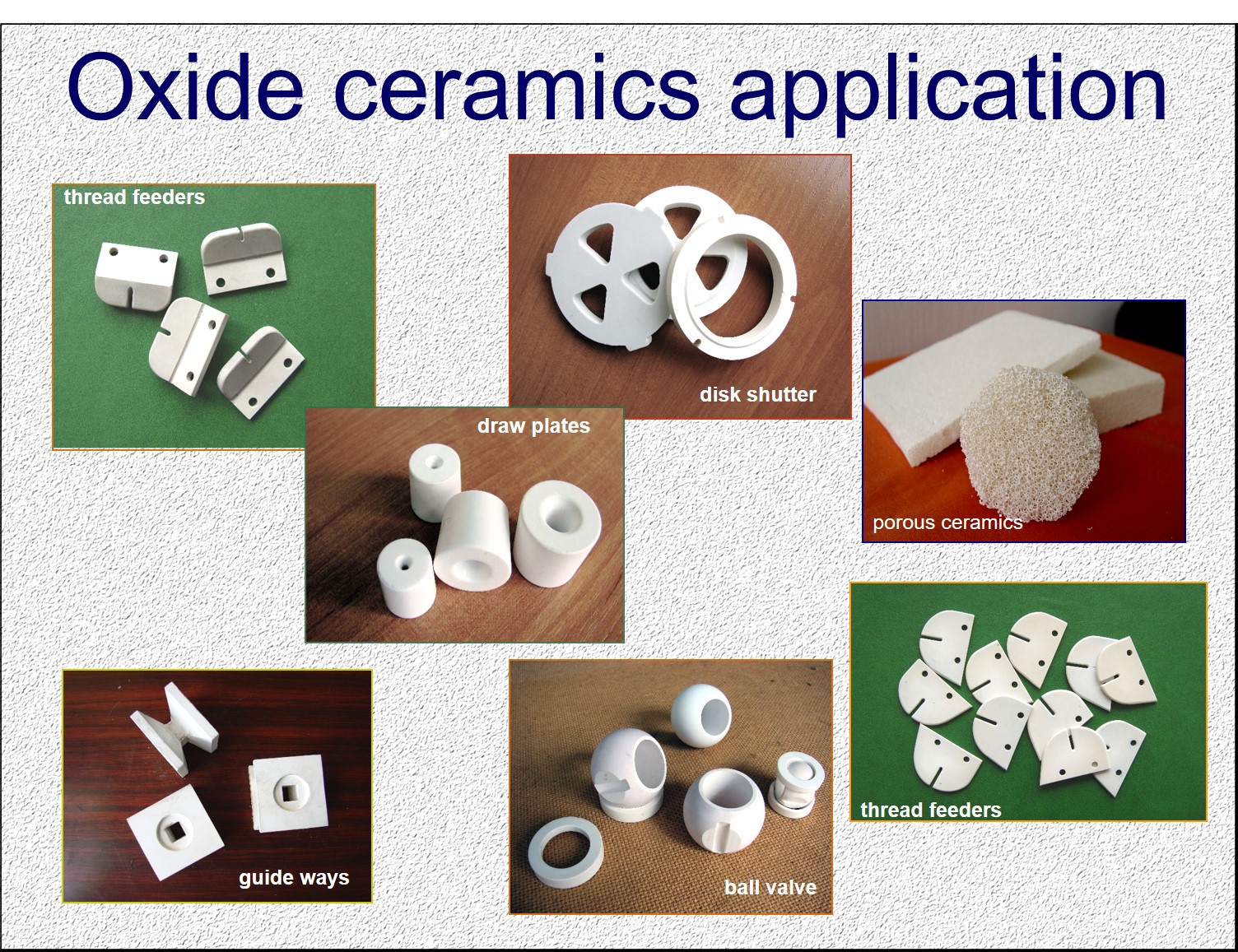

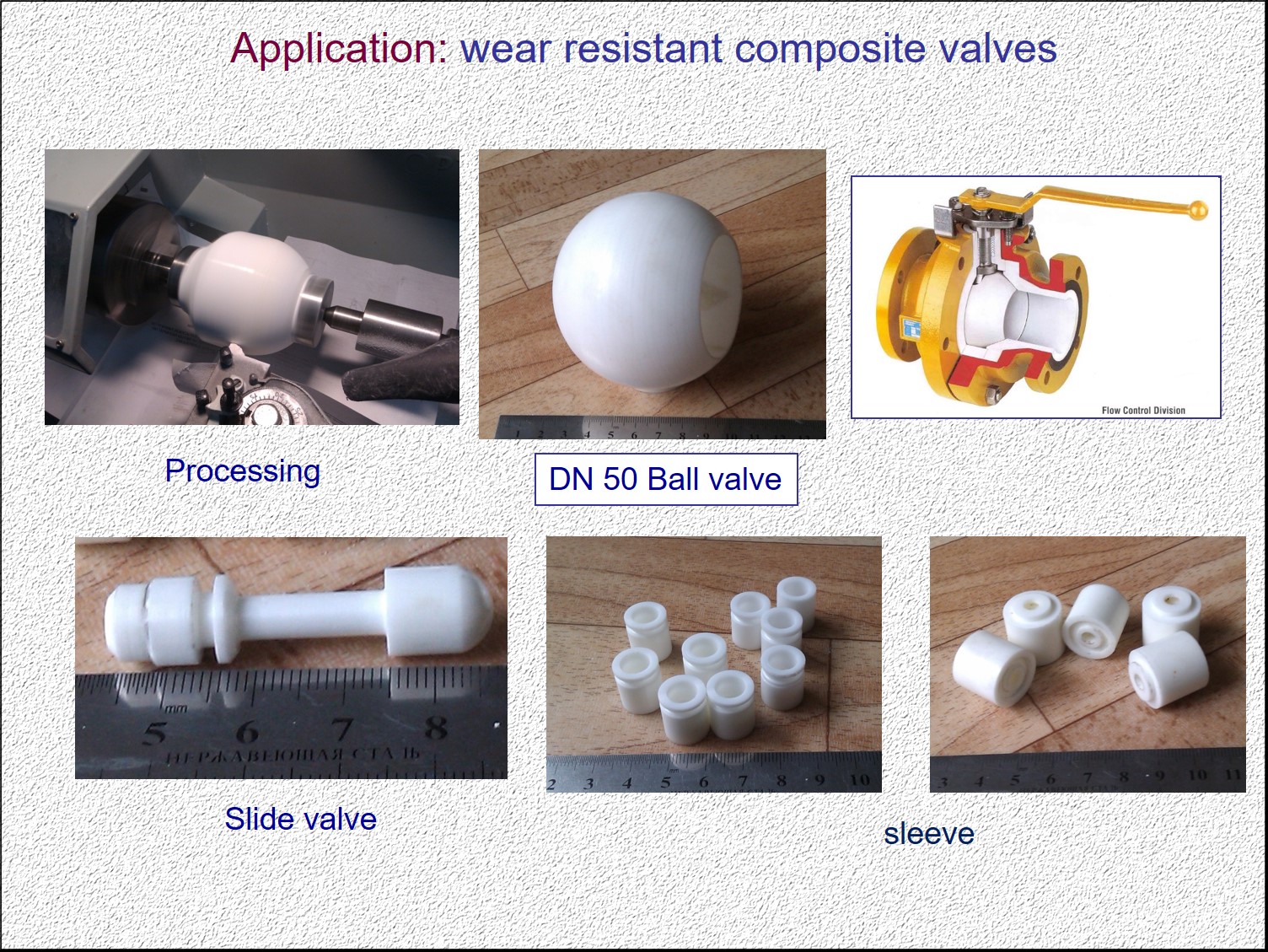

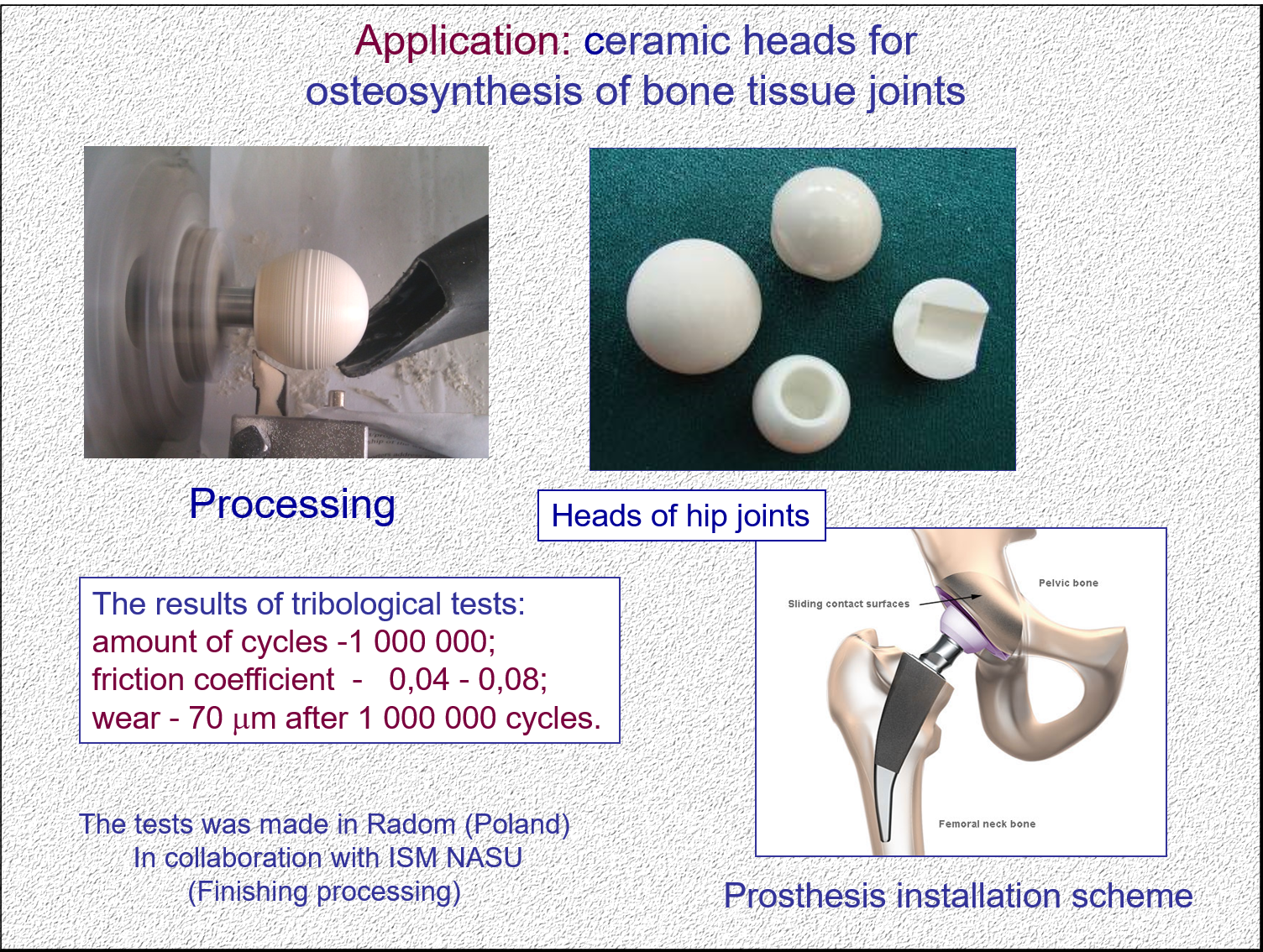

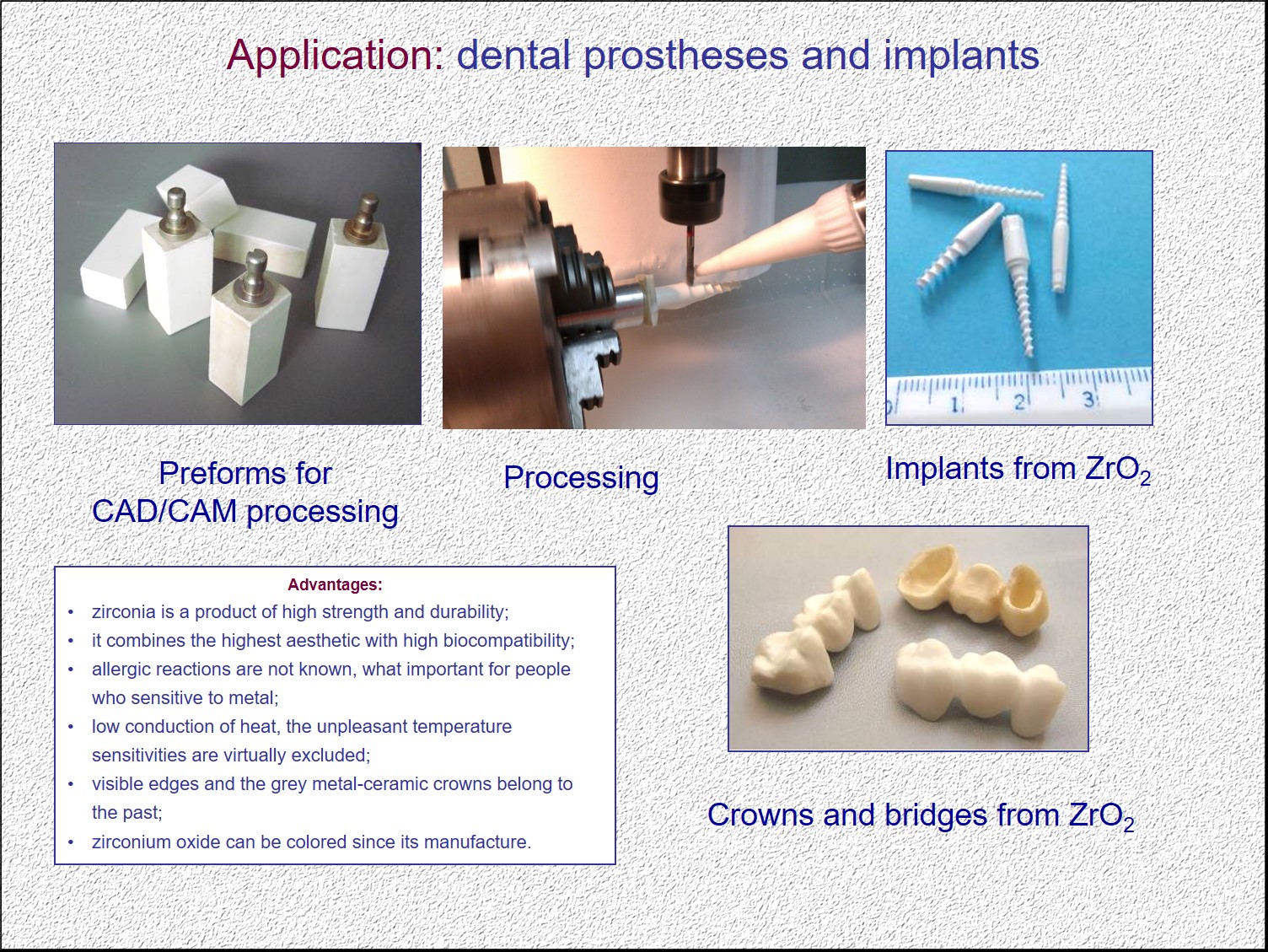

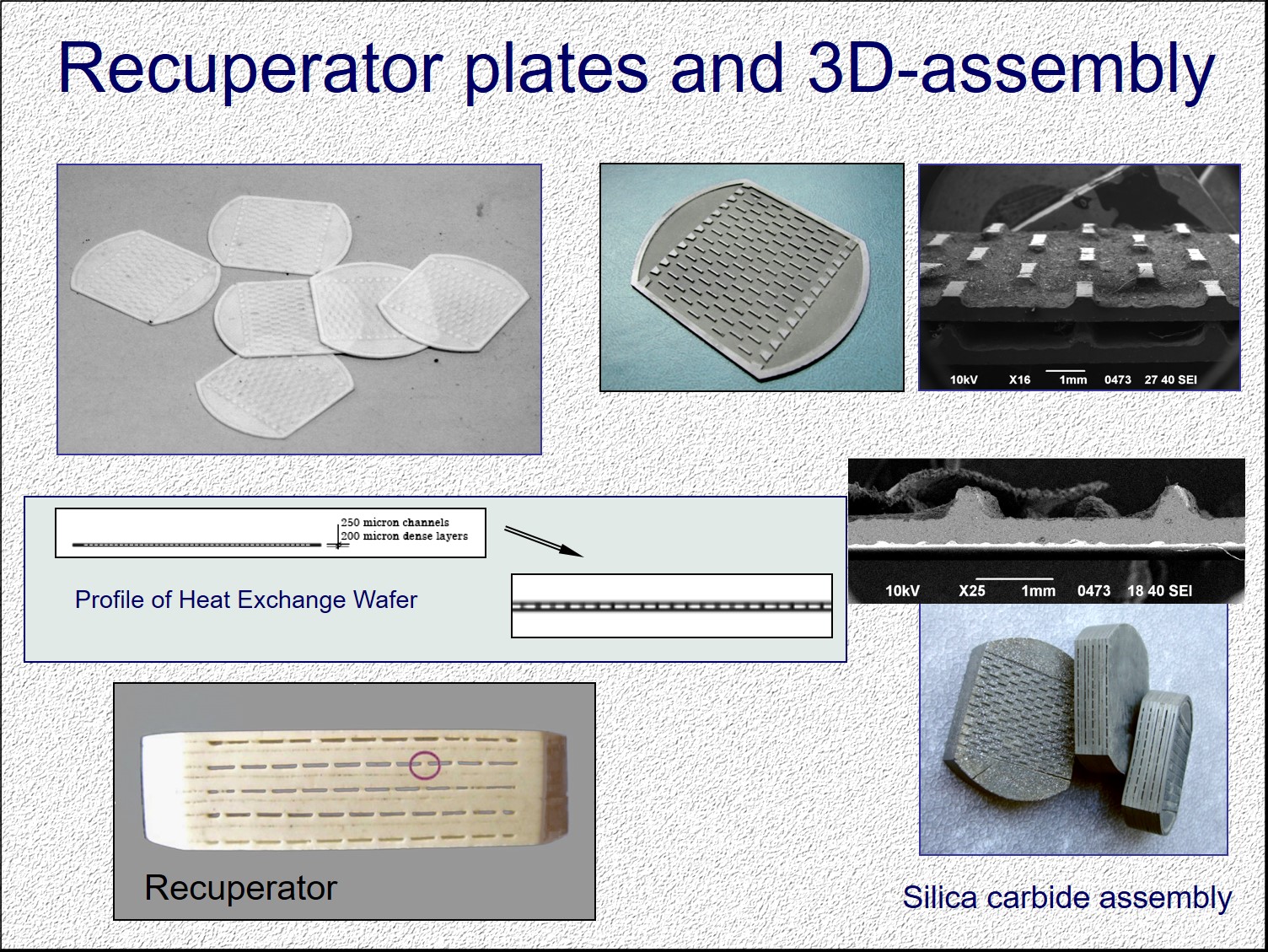

Creation of ceramic products of different functionality

Creation of ceramic products of different functionality

Our advantages

-

implementation of specific characteristics and a wide range of formulations and applications

In the production of oxide and metal nanopowders

-

the use of nanopowders of our own production in the technology of ceramics, which allows you to control its structure and physicochemical and functional properties

In obtaining ceramics