About us

Nanomaterials R&D is a manufacturing company. It makes a broad spectrum of dispersive and pressed oxide nanomaterials. The company’s work directs the creation of nanopowders for research investigation.

We propose a series of materials with pre-determined characteristics (sizes, phase and chemical composition, surface state, kind and amounts of different dopants). There are very important for investigators in the next points:

- study of structural parameters in dependence on types of bulk and surface structure defects, chemical and phase composition, size factor, kind of active surface centres, nature and amounts of dopants, other;

- investigation of the influence of structural parameters on functional characteristics of these materials.

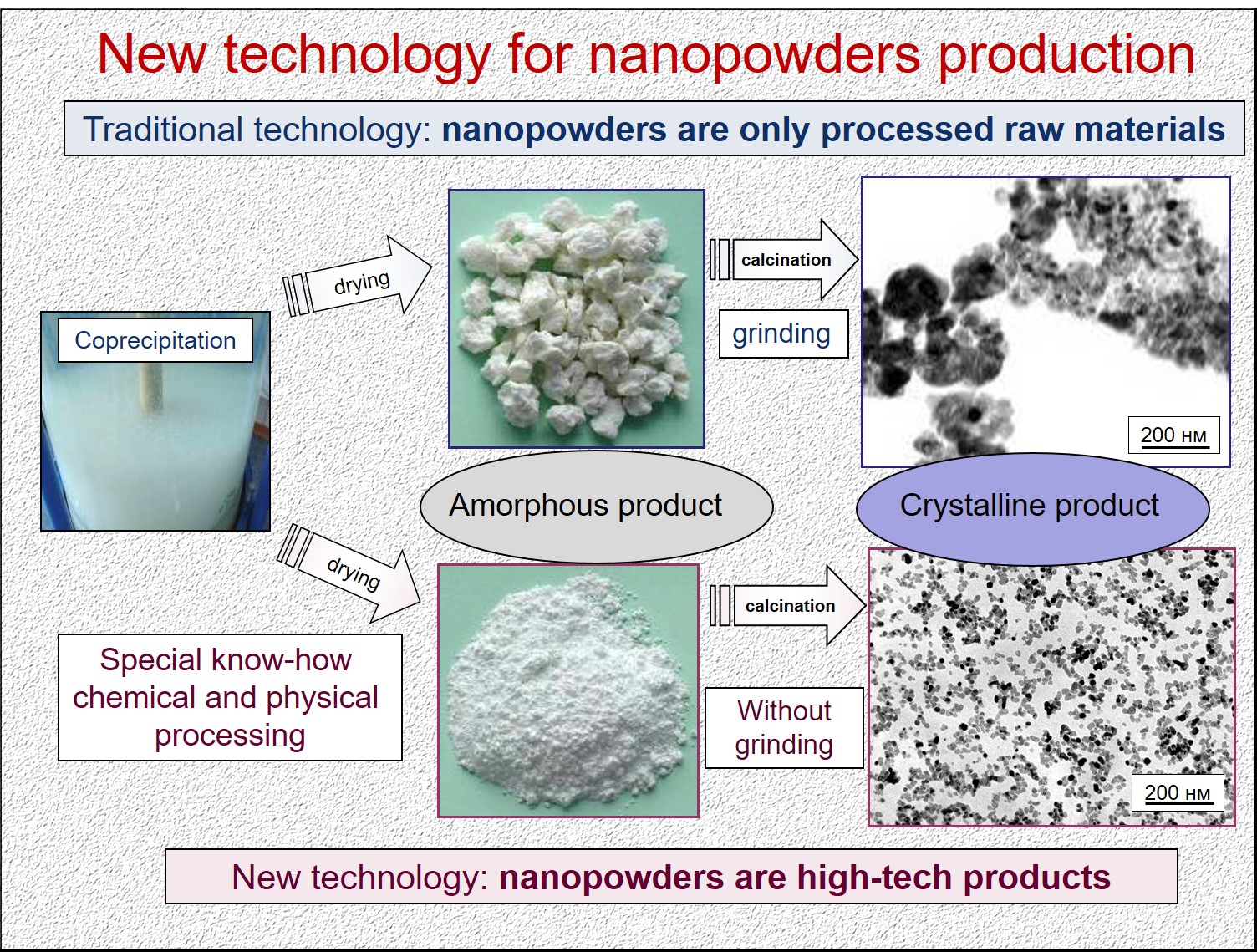

The technology of chemical co-precipitation uses for the synthesis of oxide materials. The different metal salts and agents-precipitators are used to obtain materials as in amorphous and crystalline states. A volume of synthesised product is closed to semi-industrial (up to 10 kg in the month) and easily can be updated to industrial scale.

The technology of chemical co-precipitation uses for the synthesis of oxide materials. The different metal salts and agents-precipitators are used to obtain materials as in amorphous and crystalline states. A volume of synthesised product is closed to semi-industrial (up to 10 kg in the month) and easily can be updated to industrial scale. Materials based on zirconia with complex doping are more significant in company production, but other oxide materials are also available.

We propose dispersed nanopowders and pressed or ceramic nanomaterials (in tablet, plate or cylinder form). The uniaxial or high isostatic pressure (up to 5 MPa) is used for obtaining the pressed state. It allows expanding application of such materials in research works, particularly to investigate the influence of pressure on materials forming and sintering.

- We form nanopowders for scientific investigation of nanomaterials for broad tasks

- – ceramic technologies (press, casting, 3D-printing),

- – study of different dopants on sintering materials and their construction properties:

- – study of functional properties materials for catalysis, photocatalysis, hydrogen and other alternative energy, optics, magnetic, luminescent, or other applications, et.

- For order, we propose the creation and synthesis of oxide nanomaterials with necessary for investigators characteristics, chemical and phase compositions.

- The synthesis occurs in the chemical laboratory that certified according to quality standard ISO 9001:2015.

October 2022

NRD won participation in the Horizon 2020 projects.

Researches of Nanomaterials R&D participate in the project 871284 H2020 Marie Curie SSHARE Self-sufficient humidity to electricity Innovative Radiant Adsorption System Toward Net Zero Energy Buildings, Programme “PEOPLE” – Call ID “H2020-MSCA-RISE-2019″. This project involves the participation of the following institutions: Universidade Lúsofona (Project Leader) from Portugal, NANOTECH Center, LISP, both from Ukraine, UIB from Spain. Furthermore, the project counts with following institutions as partners: IIPT, from Uzbekistan; NNRC, from Azerbaijan; TTV, Tajikistan.

This project aims to develop a novel type of Self-Sufficient Building Panels to meet low energy-consuming requirements for buildings. This integration imitates the sweat of living beings to cool or heat the indoor or outdoor environment, according to the user needs, by just using the atmospheric humidity as a source of thermal and electrical energy to power this panel.

Researches of Nanomaterials R&D participate in the project «Creation of innovative “humidity to electricity” renewable energy conversion technology towards sustainable energy challenge», acronym CATCHER, No101046307. This project approved in Pathfinder, a program from European Innovation Council that aims at identifying and supporting breakthrough technologies with the potential to scale up internationally . The project CATCHER aims to develop innovative technology to exploit the atmospheric humidity for direct conversion to the electricity, thus gain a new sustainable source of renewable energy. The project will be developed in collaboration of highly qualified teams from Portugal, Belgium, Austria, Spain and Poland.

November 2022

Secondments to Lusofona University

Lidiia Shylo and Vyacheslav Mysovets, members of the Nanomaterials R&D will carry out a personal detachment and exchange of knowledge at Universidade Lusófona de Humanidades e Tecnologias (Portugal) in the period from 10.10.2022 to 10.09.2023 under the program Horizon2020 SSHARE Project.

These two researchers will be in Lisbon invited by the Lusófona de Humanidades e Tecnologias as a member of the consortium under programme H2020-MSCA-RISE2019: Marie Skłodowska-Curie Research and Innovation Staff Exchange (RISE) project ‘SSHARE’ ‘Self-sufficient humidity to electricity Innovative Radiant Adsorption System Toward Net Zero Energy Buildings’.

These two visitors will be involved in the next research:

Lidiia Shylo – “Analysis of the influence of natural and technogenic factors on the decreasing level of generation of electric potential by a system of flooded zirconia nanoparticles”

Vyacheslav Mysovets – “Study and analysis of the surface properties of zirconium dioxide nanoparticles in the context of the environmental aspect of the process of developing a complex technology for obtaining materials for a converter to ensure a low environmental impact profile in the production process”.

December 2022

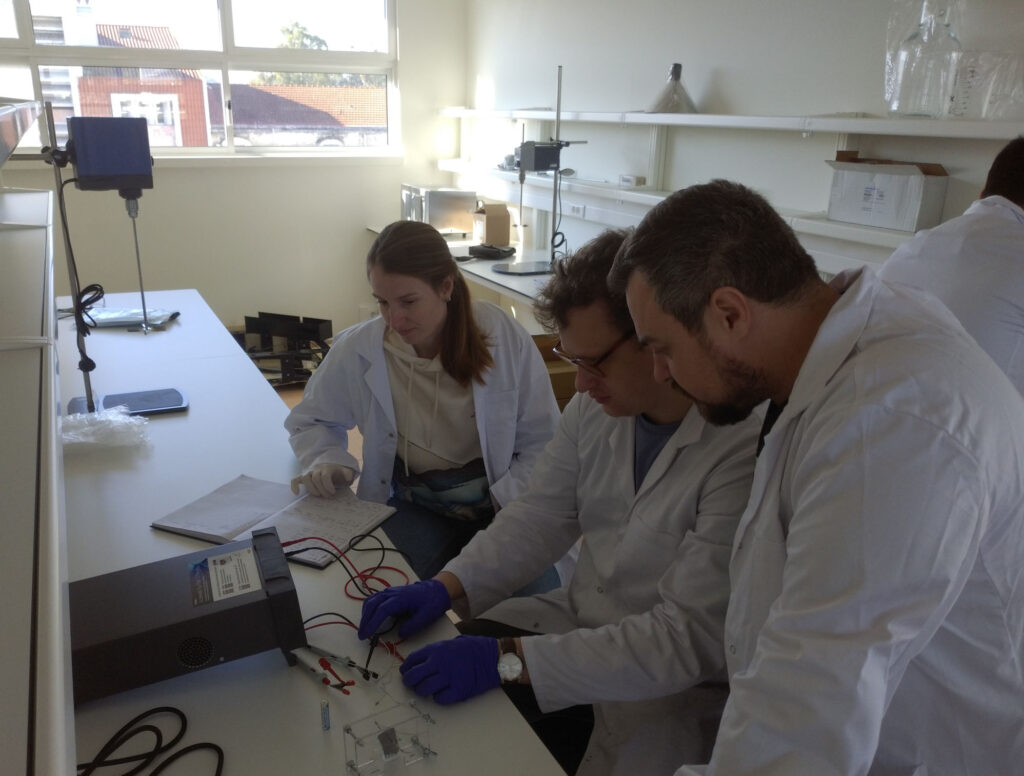

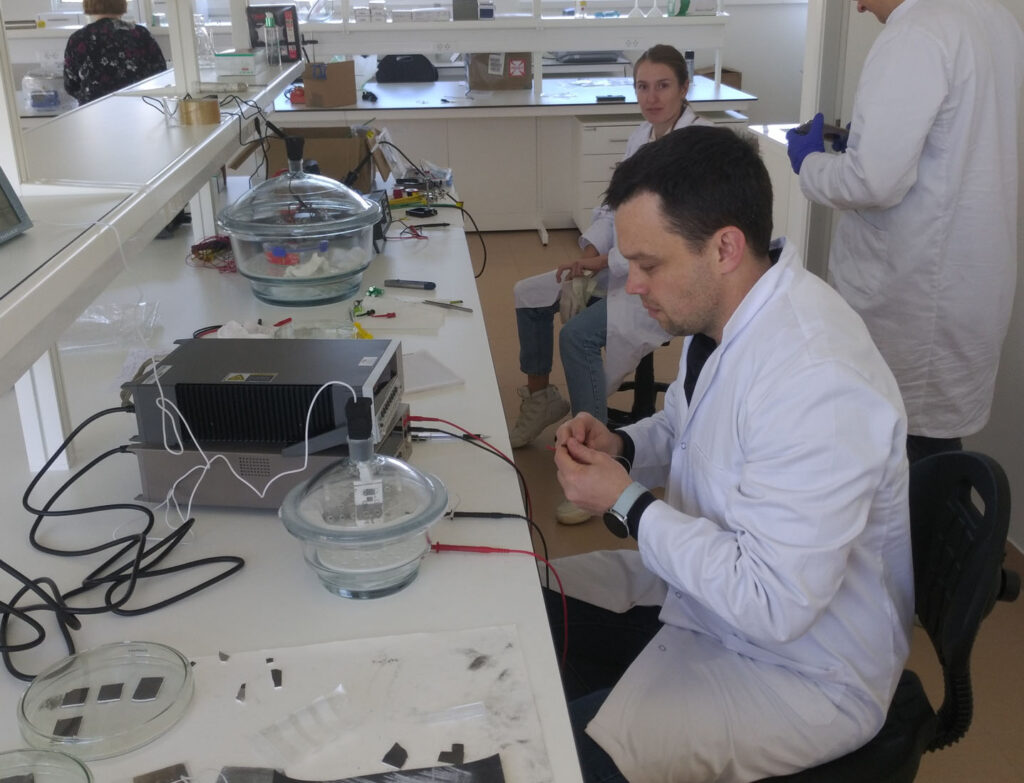

Work in the laboratory Lusofona University

February 2023

Visit of the Director of Lusofona University

January 2024

Nanomaterials Research & Development Sp. Z.O.O. take part in the project # 101129879 “Novel detector concept for medical gamma probe” – DETMED of the HORIZON-MSCA-022-SE-01. The aim of the project is to develop a high-precision, more compact prototype gamma probe for surgical operations. Within the framework of this project, the collaboration will carry out both, research and technological components using the latest research methods and technical potential and through multi-purpose business trips.

NRD team will take part in the Investigation of parameters of scintillation materials and calculation (WP2), Detector’s Module for innovative medical Gamma Probe Assembly (WP4) and Testing and calibration of the Gamma Probe prototype (WP5). NRD team members will visiting to the Partners organizations and host several Partners teams in Krakow.

May 2024

The first visiting to NRD starting. The NRD company received delegations from Azerbaijan (SETM and IRP) and Ukraine (IGIS).

Within the framework of these visits, it is planned to obtain and study scintillation materials based on YAG doped with various rare-earth metal ions. The influence of the synthesis method, particle size, and type of dopant on the structural and luminescent properties of scintillators will be studied (IGIS, NRD).

Work will also be carried out to calculate the shape, size of scintillator and shielding materials will be calculated for SiPMs detector (IRP, SETM).

A seminar “Scintillation materials: problems of synthesis and increasing the efficiency of photon detection” was held. Presentations were made by Ahmadov G. (IRP), Gorban O (NRD), Berezhnytska O (IGIS), Bacherikov Yu (IGIS).

Areas of work

-

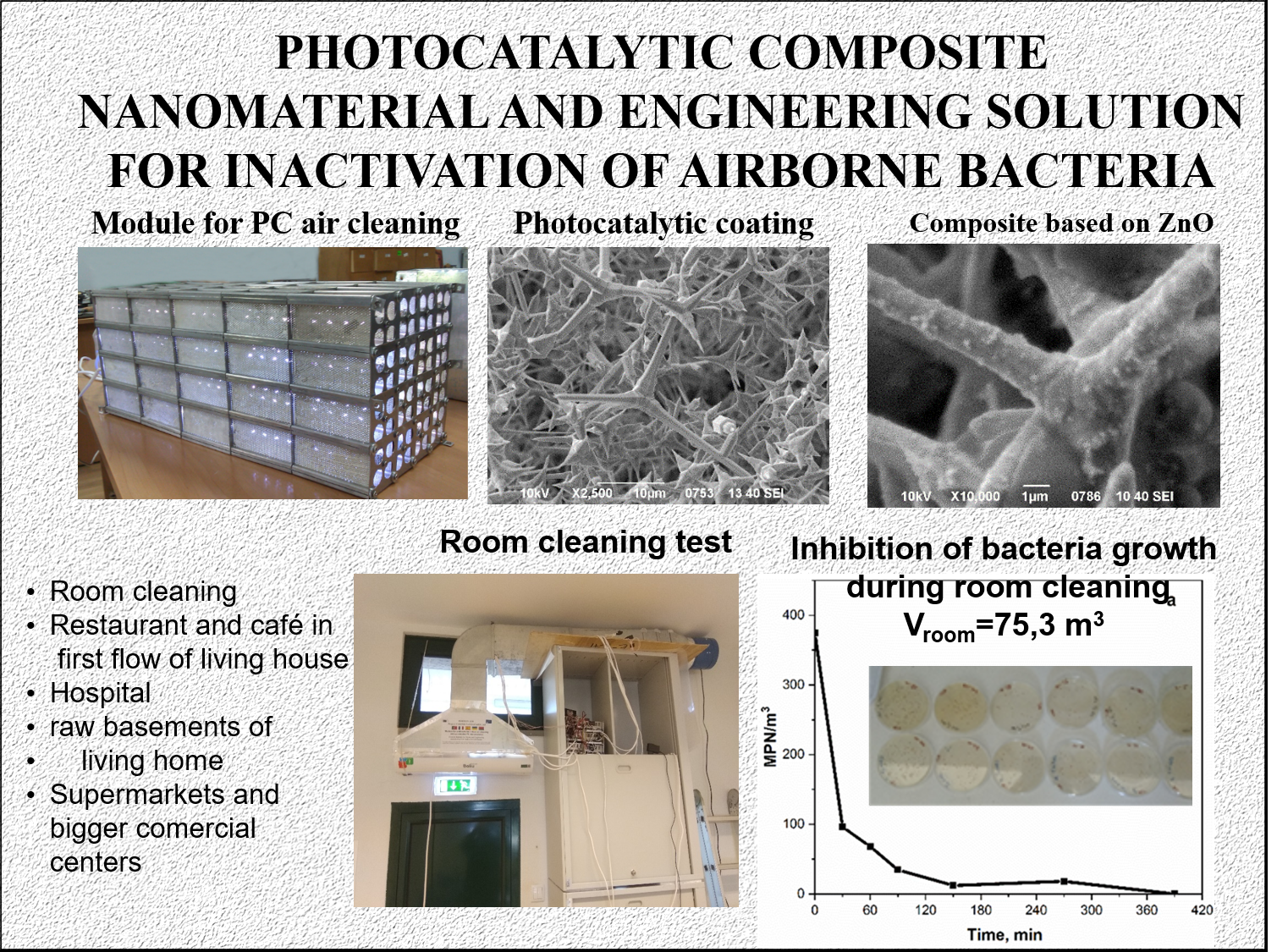

Synthesis of simple, multicomponent and composite nanomaterials for scientific research;

Synthesis of simple, multicomponent and composite nanomaterials for scientific research; -

Transfer of developed materials to production

Transfer of developed materials to production

-

Scientific and technological service for the characterization of nanomaterials

Scientific and technological service for the characterization of nanomaterials

-

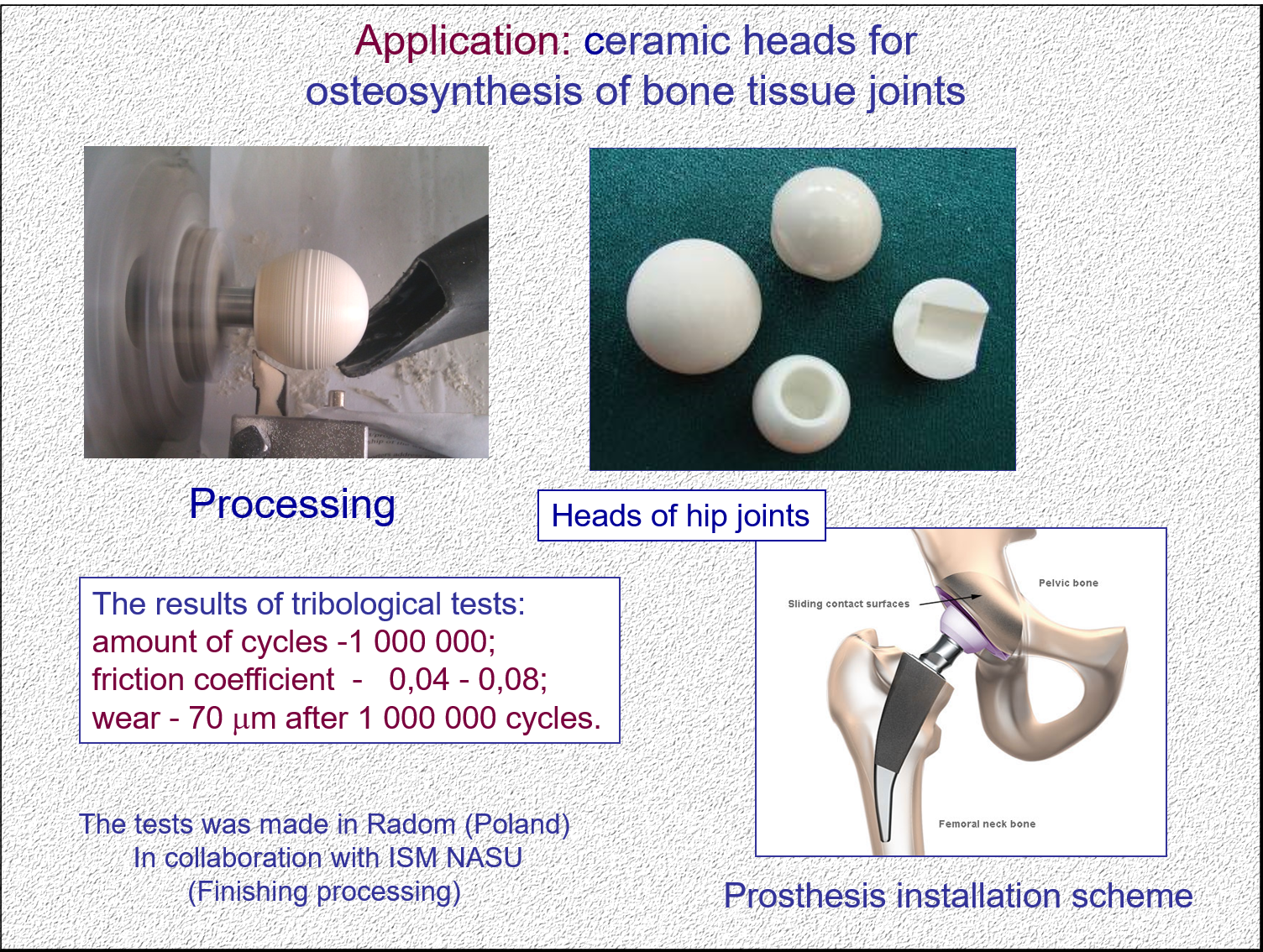

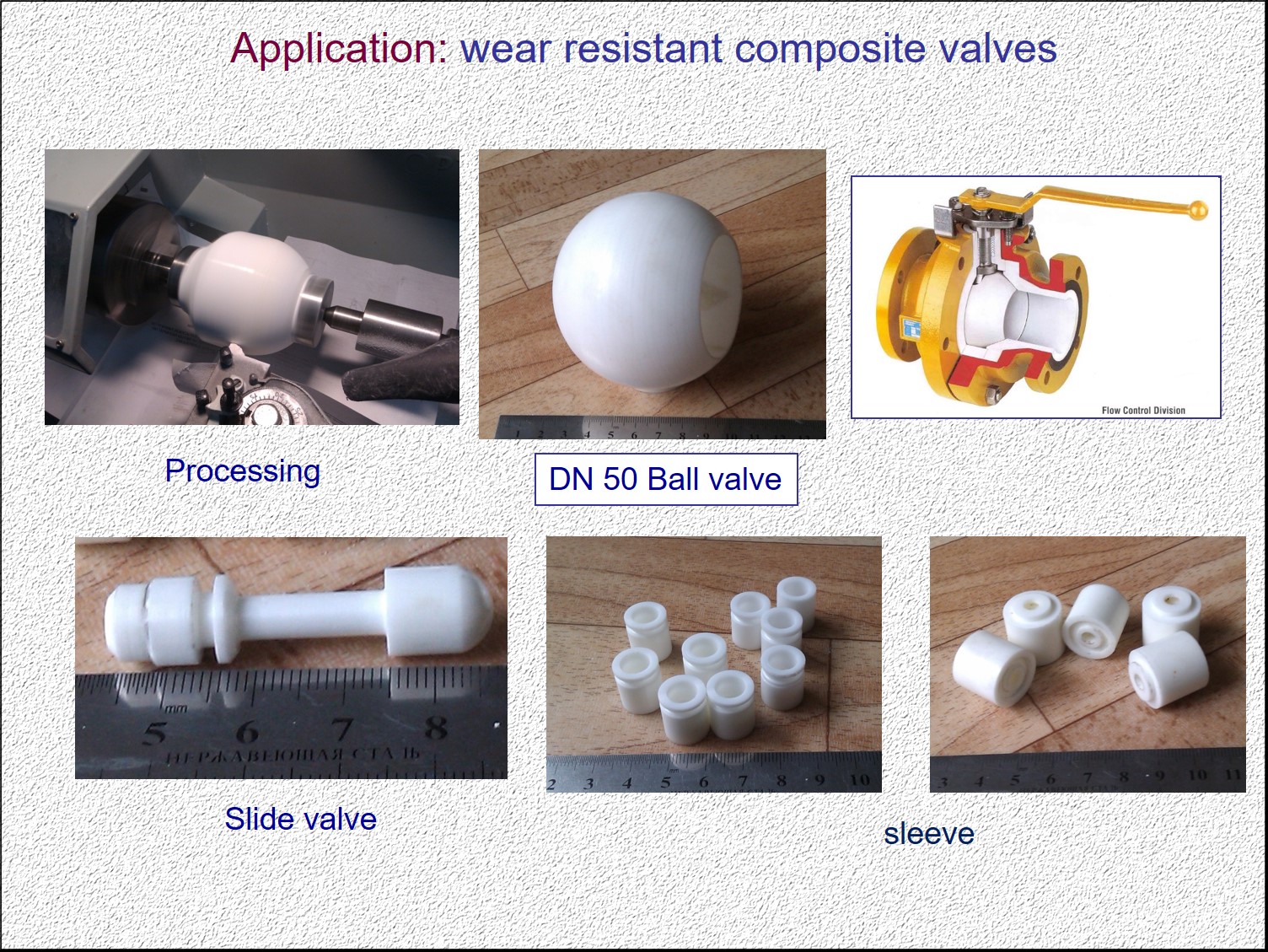

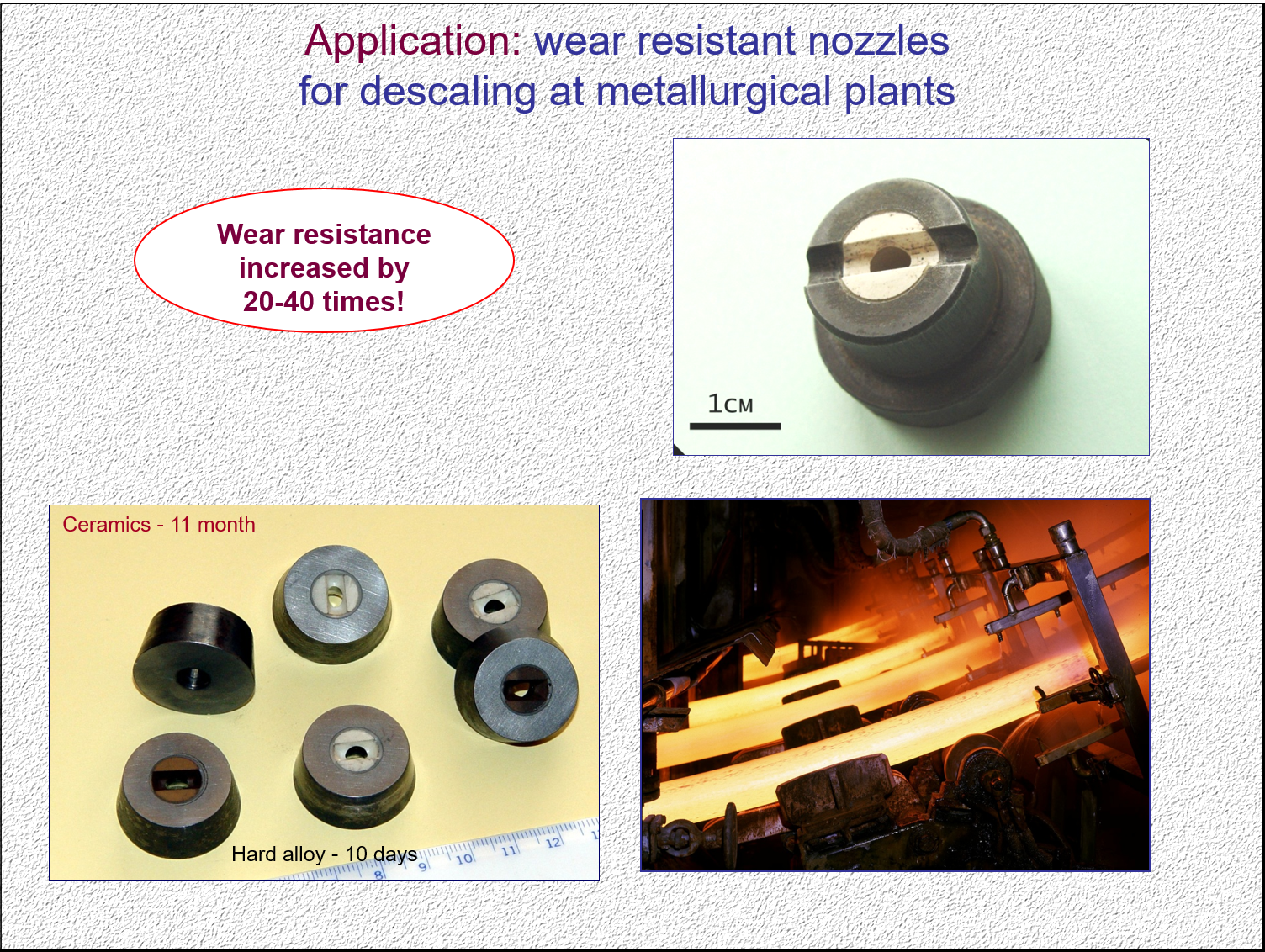

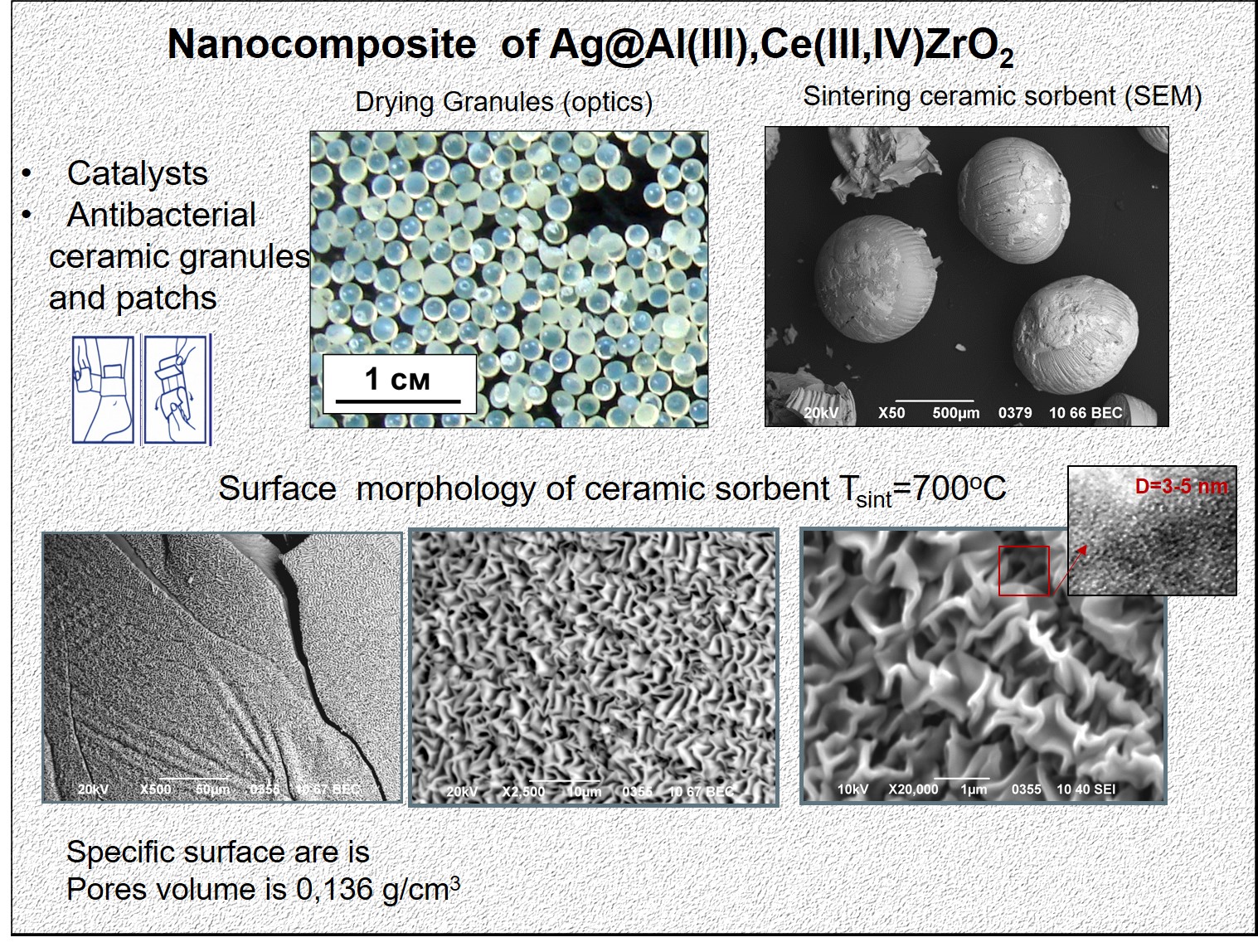

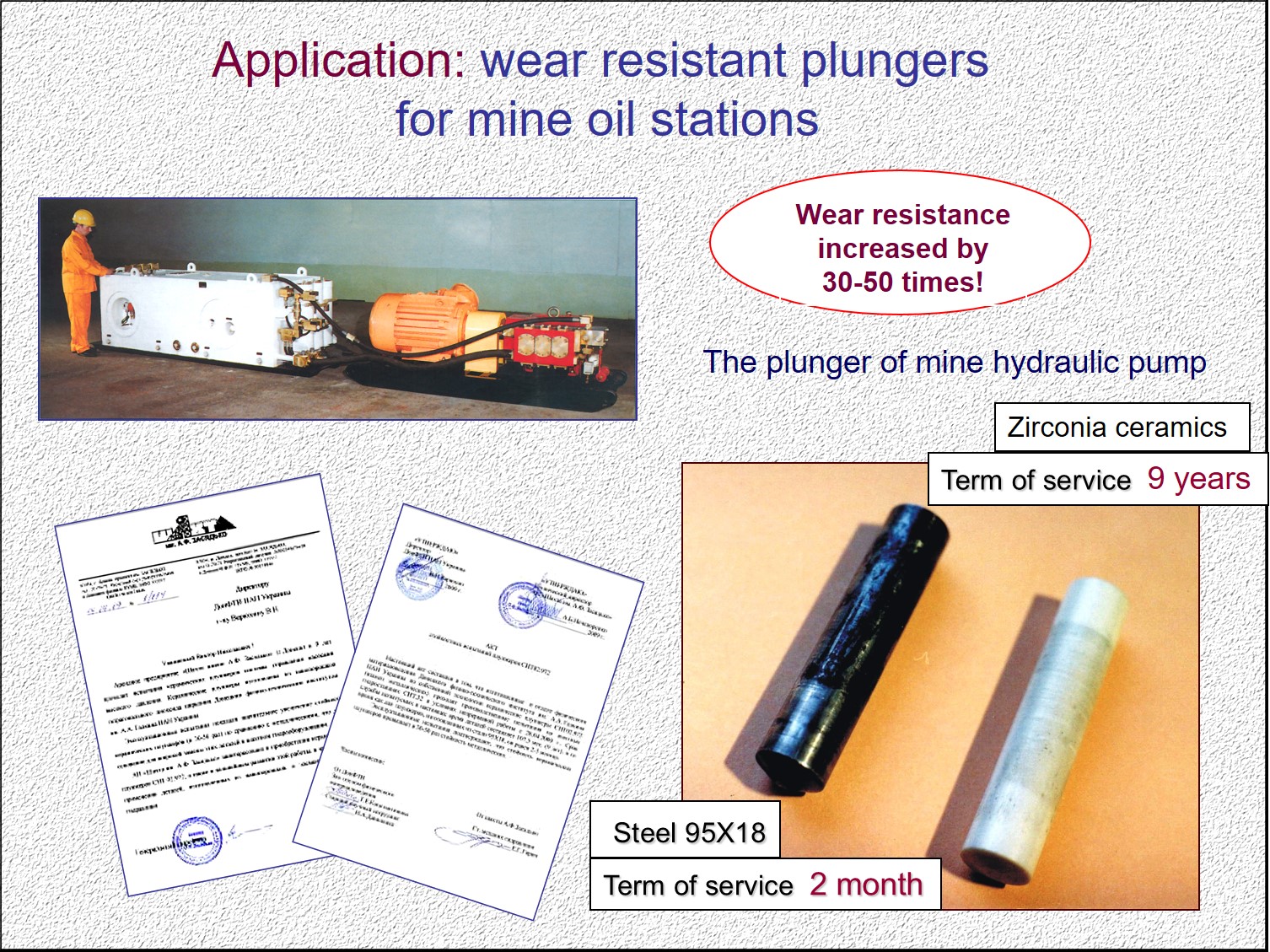

Solving the problems of improving the properties of oxide ceramic materials

Solving the problems of improving the properties of oxide ceramic materials

-

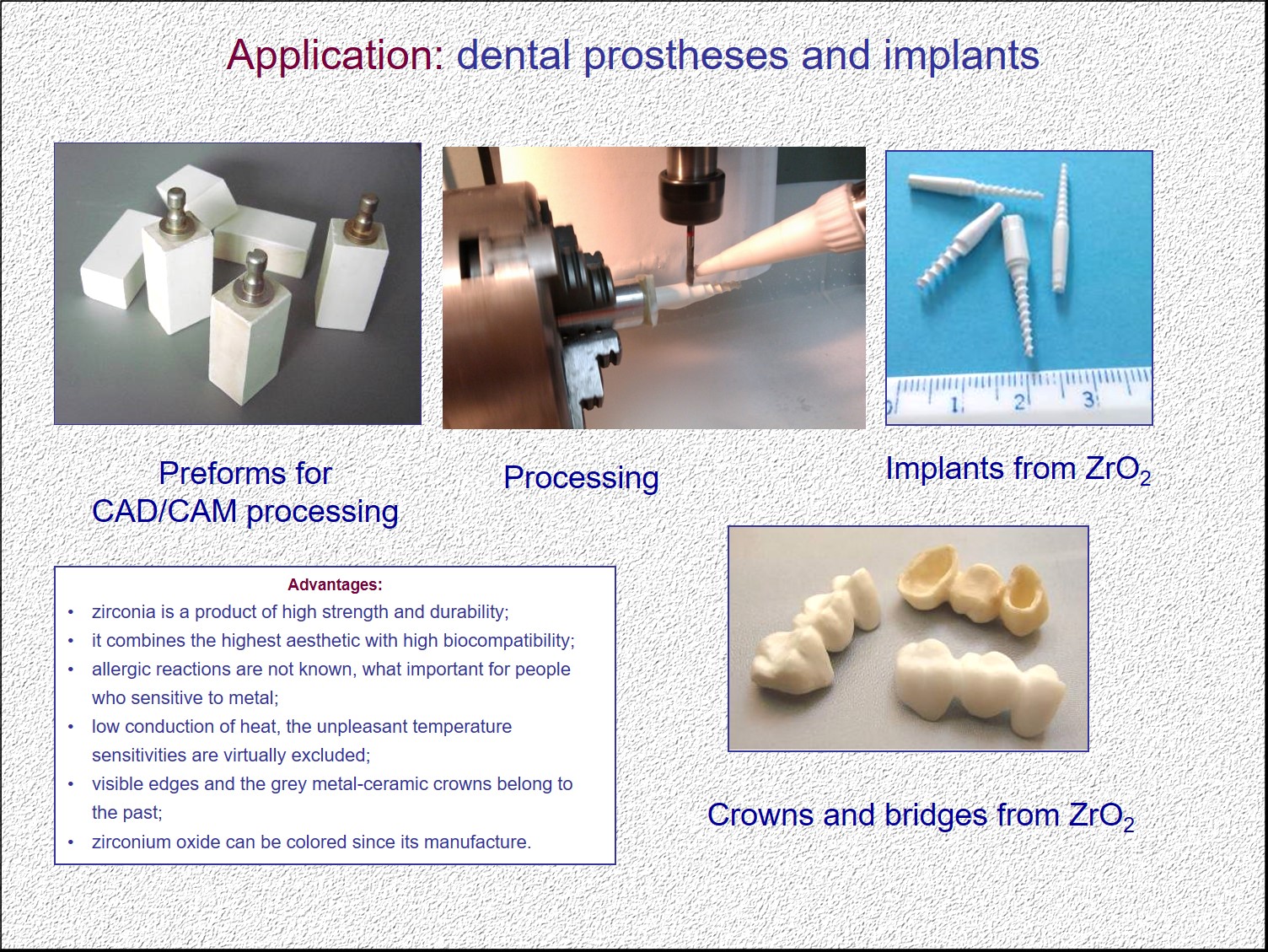

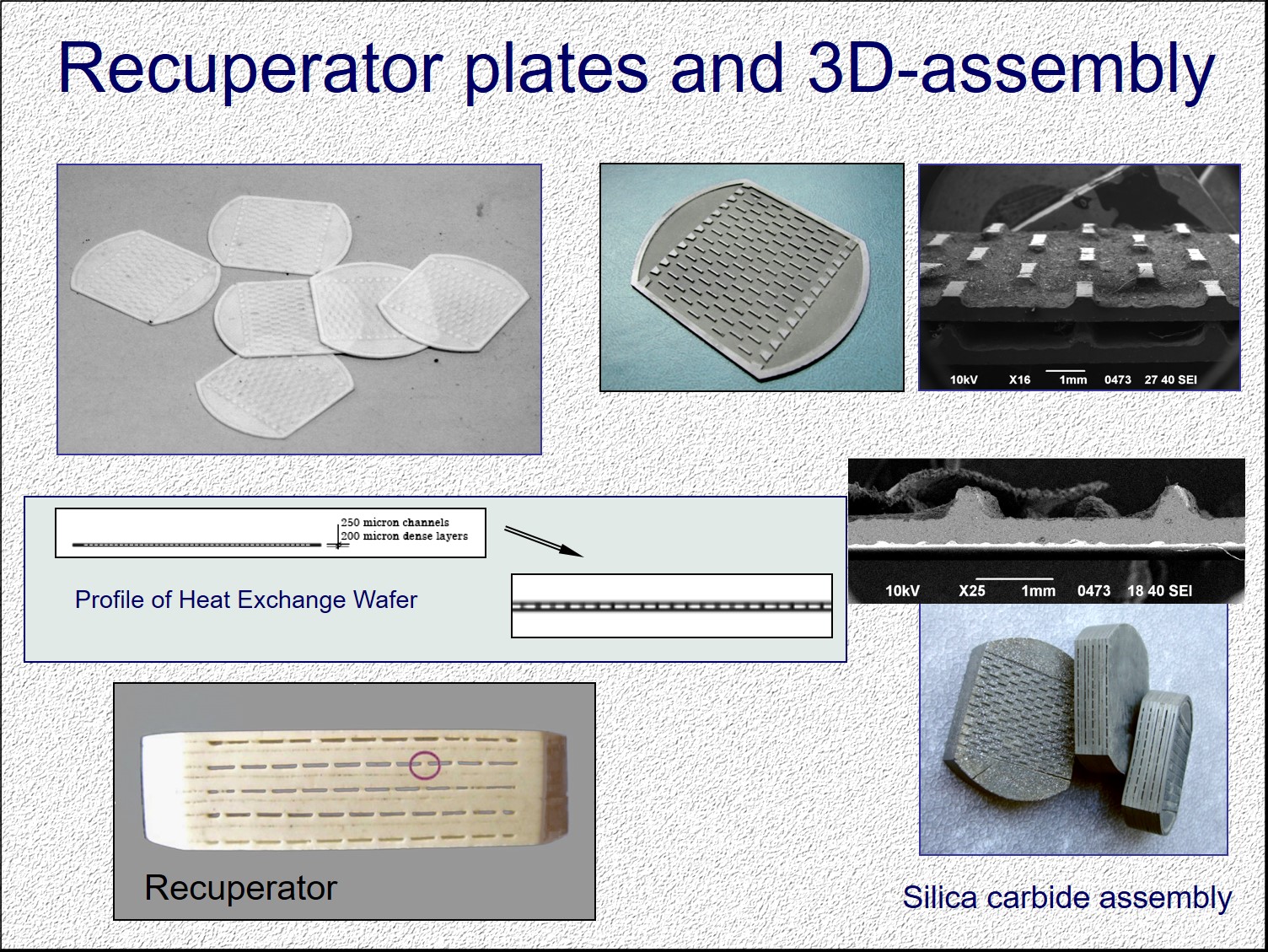

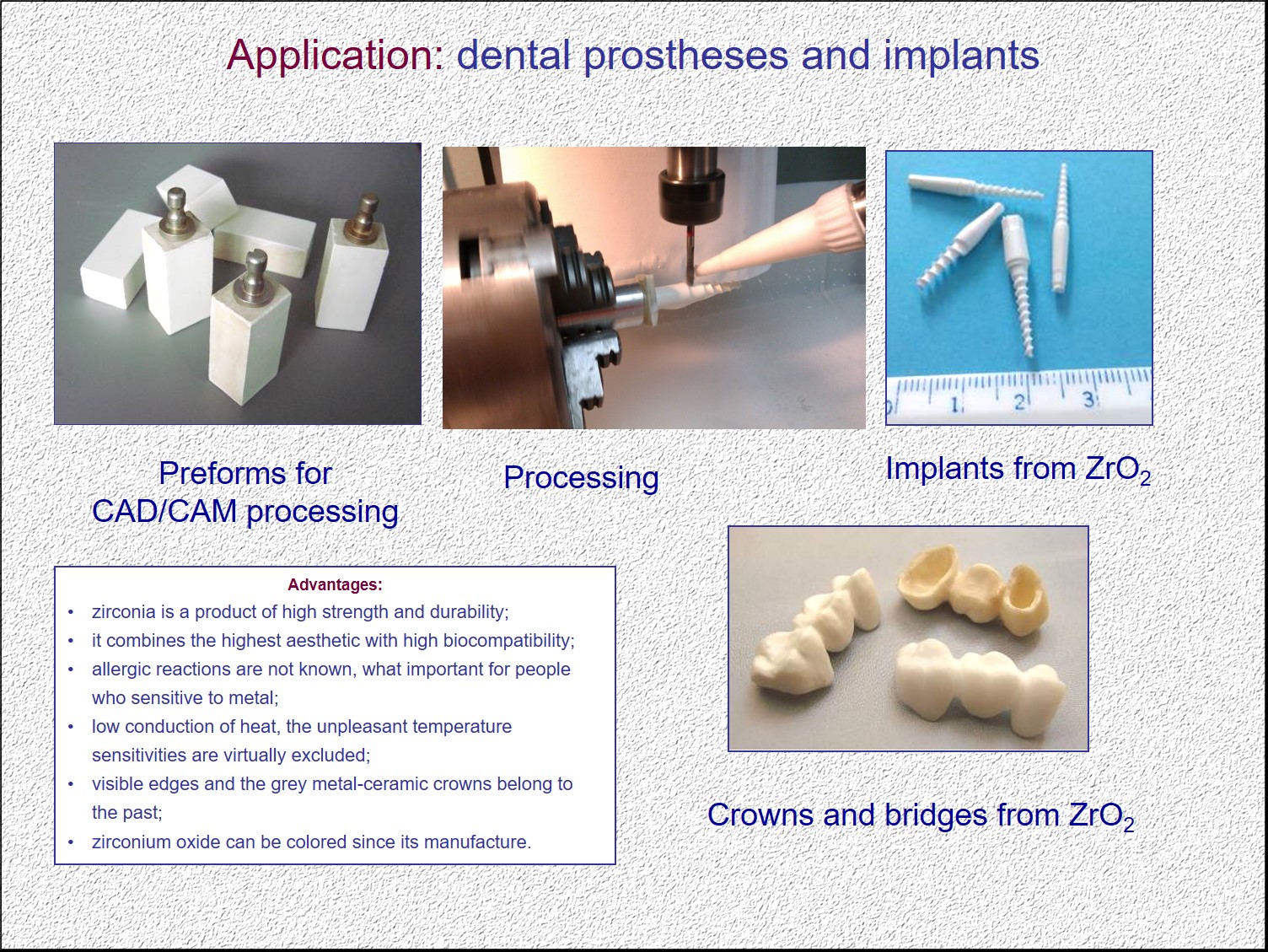

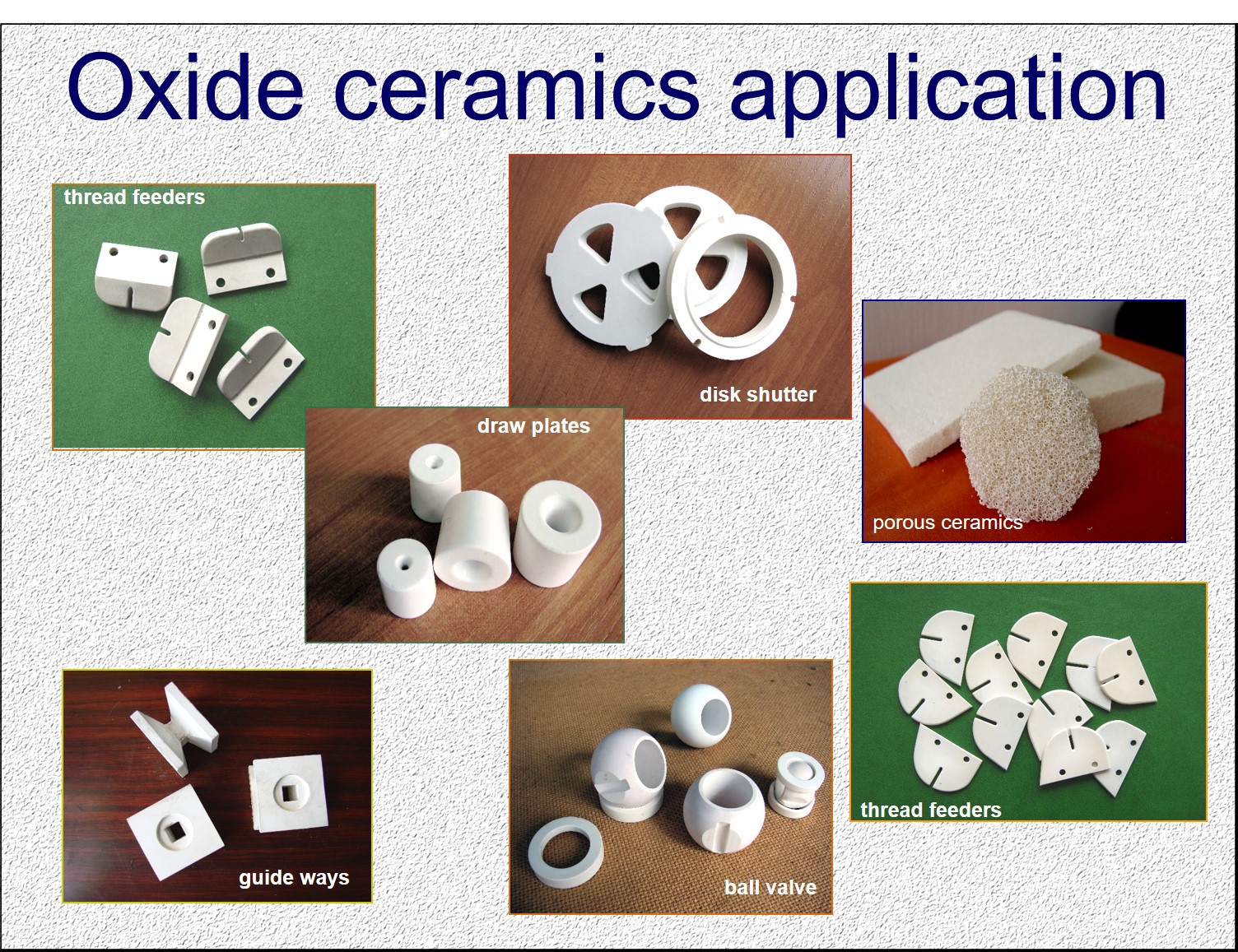

Creation of ceramic products of different functionality

Creation of ceramic products of different functionality

Our advantages

-

implementation of specific characteristics and a wide range of formulations and applications

In the production of oxide and metal nanopowders

-

the use of nanopowders of our own production in the technology of ceramics, which allows you to control its structure and physicochemical and functional properties

In obtaining ceramics